Pyramid SOT Printer VKP 80

Many aspects of handling are described directly in the SOT printer VKP 80 in practice section of the SOT documentation. This is about more far-reaching things, but they also influence error messages in practice.

When the paper runs out, a sensor detects this and an error message appears on the SOT. Operation is then no longer possible. To prevent this from happening in practice, there is another sensor that detects when the paper is almost used up. This status is then reported to the POS system. See this: Printer messages to station...

We recommend that you replace the receipt roll in good time so that the change does not take place during operating hours and may be delayed, resulting in a machine failure. This requires the appropriate lead time of the paper near end message.

Best practice: The right lead time for the paper near-end sensor

Everything has to work reliably at the Self Order Terminal - especially at peak times. An empty printer is not a minor annoyance there, but leads directly to queues, uncertainty among guests and unnecessary service calls.

The crucial question is therefore not whether a paper near-end sensor is useful, but how early it should warn you.

Determine the right lead time

The right setting depends directly on your operating process.

A simple practical example:

If your employees do not realistically have the opportunity to change the receipt roll during a peak period of two hours, for example, the sensor must be set so that it reliably reports before this peak period begins: The paper will soon run out.

The sensor communicates this information in good time - for example at an appropriately equipped checkout station - and gives your team the opportunity to react before the peak time, not in the middle of it.

Why residual paper is consciously accepted

This procedure can lead to thermal paper not being used up completely. This is precisely why we rely on 150-metre receipt rolls for the Pyramid SOT as best practice:

They offer a high level of operational reliability and significantly reduce the frequency of such residual quantities.

If you want to avoid residual quantities as far as possible, there is only one way:

Your employees must be able to change roles regularly and in a targeted manner - and be given the time and training to do so. In this case, the sensor can be adjusted later accordingly.

Both are legitimate. Only one thing is important:

Make a conscious decision - otherwise the appliances will fail just when you need them most.

Practical tip for everyday life

The following procedure is recommended if you wish to utilise residual quantities in a targeted manner:

Use opened rolls during quiet periods or on appliances where a quick change is possible at any time.

Set the sensor differently for these devices.

The secure setting remains in place for highly frequented terminals.

Or - quite pragmatically:

Accept that the timely disposal of small residual quantities is in many cases the better solution, both ecologically and organisationally, than a terminal breakdown in the rush hour.

Do not forget training

As good as the technology is, it only works if your team understands it.

Provide your employees with targeted training:

-

what sensor messages look like,

-

what these mean,

-

and when paper changes should be made according to your specifications.

Conclusion

The paper near-end sensor is not a savings instrument, but an availability instrument. Correctly adjusted, it protects:

-

the smooth running of the Self Order Terminal,

-

Your guests from frustration,

-

and your team from unnecessary stress during busy periods.

Operational reliability beats residual optimisation - especially at peak times.

Further topics: Directory: Best Practice

Adjusting the sensor

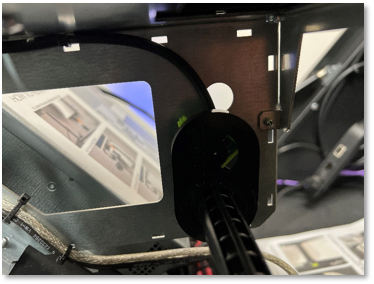

To access the sensor, first open the SOT. Now remove the receipt roll from the device:

At the end of the receipt roll holder is a light green adjustment for the eccentric:

This eccentric has different positions. The following pictures show how the lever can be adjusted:

The settings work as follows: eccentric to the rear for an earlier warning, eccentric to the front for a later warning (in the illustrations, rear = left and forward = right).

For the person who is to use the lever, front and back are clearer even if it looks strange in the photos.

Select the appropriate setting based on the best practice above, then reload the receipt roll paper and close the SOT.

If the setting for the sensor has been adjusted, the paper must be reloaded for the sensor to adopt this setting.

(if you made the setting while the paper was still in the printer).

Further topics: SOT printer VKP 80 in practice

Back to the overarching topic: Hardware for Hypersoft