Using the Production Monitor

The production monitor operates largely on the basis of the production instructions. However, it has different modes:

- In Normal mode, you select an item, enter the quantity, and start production.

- In MRP mode, the list is filled using requests from the MRP monitor. Items can be selected as total quantities or partial quantities. If several production monitors are used, employees can share the production tasks.

- In Hold mode, you can create a parts list with the items you need to produce. With this list you can take the items out of stock and equip the kitchen post.

All elements are optimized for touchscreen operation and allow convenient production control.

Since you can store weight tolerances for each work step, consumption tolerances occur at the end of a production run. The CONTROLLER is informed about the actual consumption and accordingly more or less goods are transferred into the production.

Start Produce from the Controllerprogram group.

To set up an automatic start on a station, use Remote Commander.

Further topics: Remote Commander

|

product list

|

The product list shows you all items that are either in MRP mode or available in Normal mode (all products). Select the desired product.

Items with the Discontinued Items property are not displayed.

|

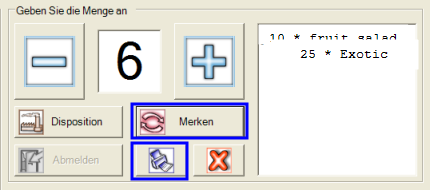

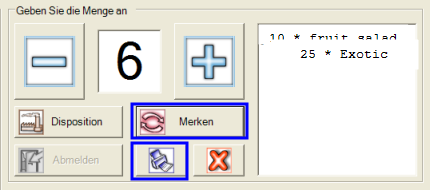

| quantity |

The number you want to create from the product is determined by you in normal mode. In MRP mode, the number is specified by the MRP monitor. However, you can reduce the number (the remaining quantity remains in the list) or increase it. The + and - keys as well as the keyboard are available for this purpose.

Production is also possible with quantities with decimal places. ( e.g.: 0,5 pieces )

However, this is not possible for products with individual work steps or availability items, a corresponding message is then displayed.

|

| Produce |

Starts the production monitor. |

|

disposition

and

normal

|

Use this switch to switch between Normal mode and Disposition mode. |

| Remember |

With Hold, you initiate the Hold mode for determining the demand for items.

A component list shows you all items which you need to manufacture the products listed with note. After the print we discard the list.

- Select an item and enter the desired quantity.

- Click on Remember.

- Repeat step 1. and 2. until you have listed all items.

- Click on the Print icon to print the parts list to the set front office printer (the parts list printer must be set up and started).

Press the X button to cancel the mode.

|

|

Reprint barcodes

|

You can select an item at any time, enter the desired number and use the Reprint barcodes button to obtain the number of barcode labels for this item. |

| Search a product |

Enter a text to find the item in the full-text search list. The Continue search button takes you to the next match. |

Further topics: General information on production control

Back to the overarching topic: Production monitor