Generate purchase requisitions

You can use the MRP monitor to generate order proposals for vendors. These order proposals can then be transferred to the order centre for each supplier.

Stock specifications are a prerequisite for purchase orders. We recommend the use of the refill type when ordering from suppliers. Normally items are delivered from the suppliers to the main warehouse. The following description refers to this standard.

- Go to the placement dialog in the MRP monitor.

- Select the main warehouse as your destination.

- Choose between replenishment to target stock (standard) and replenishment when minimum stock level falls below.

- Press Book & Print.

- Launch the Order Centre.

- A message appears asking you to copy the purchase order from the MRP monitor. Once you have done this, the order proposal is in the Purchase requisitions tab of the program.

By default, no supplier is selected. You can select individual suppliers from the list or use the Select all suppliers button. With Generate purchase requisitions for selected vendors, you receive an order proposal for each vendor.

Select DecideLater to skip the dialog.

Choose Rejectrequirements to delete the order proposals.

You can Trigger purchase requisitions directly during placementskip intermediate steps with this option.

Orders not yet delivered...

Please note that in addition to all the settings for the stock specifications, purchase orders that have already been created and purchase requisitions are also taken into account. Example: If the MRP monitor has already calculated and posted the requirements for 100 oranges, these are taken into account when creating a new order proposal and these 100 oranges are not ordered again. If you do not want to do this, delete the existing transaction and create a new order proposal.

In the MCP, an exclamation mark appears in the footer in case there are purchase requisitions:

When starting Order from supplier, a message appears. Choose Generate purchase requisition to copy the purchase requisition.

Demand adjustment or turnover-based ordering

This calculation of the Order Centre also reacts to the specifications of the percentage adjustment. For example, if you expect 20% more turnover because of an extra sales day, you can set the disposition monitor to +20% and then calculate the order. (Switch off any automatic mode that may be in use beforehand and, after ordering, set back to 0 % and put any automatic mode that has been switched off back into operation).

If you want to calculate this on a sales forecast, simply determine for which standard sales you have set up your inventory management and determine the estimated variance for the upcoming ordering process and the planned period of use of the goods (usually the period of use is that until the next order). Then you know what percentage you need differently and apply it as described above.

The percentage adjustment is intended for exactly these things and the algorithm can take many things into account. The maximum stock value in the stock specifications in the item master may have to be applied in this context. Example: You always have a magnum bottle of champagne as target stock, if you increase the stock by 1%, the system would request a second bottle. The item is therefore blocked with 1 as the maximum stock against overstocking. Similarly, if storage capacity is limited, you can only refrigerate 500 kg of meat, for example, and must take this into account by setting maximum stocks.

The algorithm also takes into account the repackaging of the order units, the current remaining stock and expected deliveries. Example: 100 kg target stock. A purchase order is increased by +25%, so the target stock is now valuated as 125 kg. If there are still 30 kg left, 95 will be ordered.

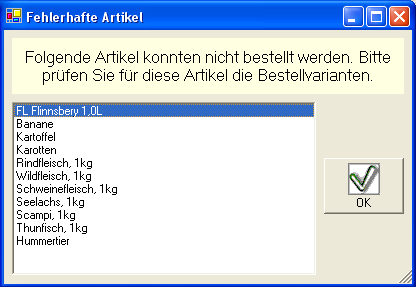

item master data verification

When you receive this message, the system wants to order items that are not fully set up. You should review, correct and repeat the order. This error message cannot be reset, but must be processed.

Deletion of purchase requisitions

Purchase requisitions can be deleted in the note on transfer. Orders that have already been processed can be deleted in the Order from suppliers program. Once the goods have been posted to the warehouse, the transaction can no longer be deleted.

Back to the overarching topic: Disposition monitor