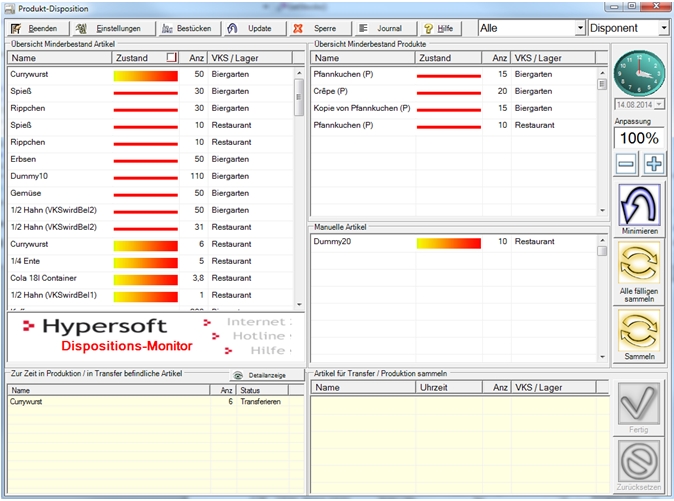

disposition monitor

The MRP monitor is used for just-in-time delivery. It monitors the undercutting of the inventory targets under consideration of the current inventory (on the basis of the inventory service).

The most important services of the MRP monitor:

- Before the start of the sale, you can load the points of sale.

- During operation, the MRP monitor monitors stocks and can request items.

- The operating mode can be changed between manual and automatic at any time.

- The stock specifications can be overridden spontaneously on a percentage basis to meet current or unforeseen requirements.

- Order proposals to suppliers can be created at any time.

- As an option, perishable goods can be automatically rebooked at the end of opening hours.

- The MRP monitor can create production instructions.

Further topics:

Generate purchase requisitions

Position of the MRP monitor

The MRP monitor should be positioned at a central location for the goods movements. It must be accessible to employees who manage the stock with it and stock the sales points.

If you use Just In Time Scheduling - that is, reordering during site operation - you should set up the MRP monitor in the warehouse or at a point of sale. The MRP monitor must be active for this. If you use the MRP monitor mainly for stocking and for purchase orders with vendors, you can also start it in the back office.

Hardware requirements

The hardware requirements depend on the number of bookings and especially on the number of items. However, the disposition monitor belongs rather to the programs that should be used with faster hardware.

Back to the overarching topic: Stock Management