Best practice for inventory management

Stock management offers many possibilities - but not every company needs the same depth of control. If you do not need to monitor goods closely and use the system primarily for orientation, you can skip this chapter or be guided to relevant sections via other topics.

For all others:

The better you understand the tools, the more efficient your control concept will be - and the more directly you will benefit from it.

Automation

The automatic processing of goods movements relieves your team and ensures transparent, traceable stocks. Can be automated:

-

Supplier processes

-

Orders to suppliers

-

automatic goods receipt postings

-

Internal flow of goods

-

Stocking (automatic replenishment) of warehouses and points of sale

-

internal forwarding and the manufacture of own products

-

Just-in-time delivery to individual points of sale

This results in a smooth, error-free flow of goods - regardless of the workload in day-to-day business.

quality management

The controller not only supports you with inventories, but also with quality assurance:

-

Kanban control for particularly sensitive areas

-

optimum preparation of all points of sale

-

Production specifications and recipes for standardised quality - across all locations

-

clear, unambiguous production instructions for consistent results

This makes quality measurable, traceable and easily reproducible.

Teamwork between cashier and controller

The automatic checkout interface seamlessly connects both worlds:

-

common article master for POS and stock management

-

Recipe articles including side dish changes

-

tax-deductible loss postings

-

Mapping of simple to complex operating structures

-

Orders and internal stock transfers without rigid target stock levels

The result: a system that works exactly as flexibly as your business needs it to.

Control

Reliable stock control is the basis of any functioning automation system.

Without regular checks:

-

theoretical stocks are unreliable,

-

incorrect postings occur,

-

the planning becomes imprecise,

-

the system loses efficiency.

With Hypersoft Stock Management you benefit in several ways:

-

precise control down to the individual point of sale

-

complete traceability of all stock movements

-

clear analyses of the cost of goods sold

Aim of each control cycle:

The actual stock should be as close as possible to the theoretical stock.

How the control cycle works

-

Record actual stock (control recording)

-

Evaluate comparison with theoretical stock

-

Recognising differences

-

start a new, clean control cycle

In the Stock Reporter, you can analyse deviations and identify the need for optimisation at any time.

Best practice for goods movements - control enables automation

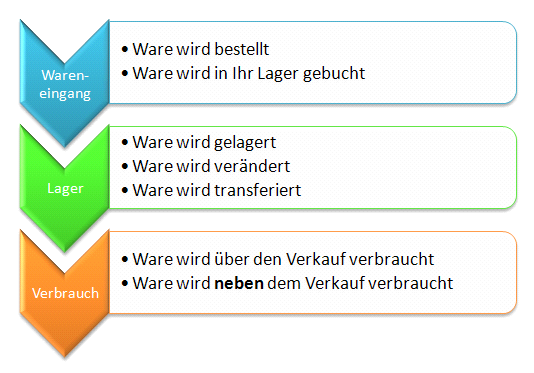

Goods movements form the foundation of the entire stock management system.

In the previous chapters, you have already learnt about the options available to you and the benefits of automated merchandise management. The important thing is:

Automation only works reliably if stocks are checked correctly and regularly.

To illustrate the logic of the movement of goods, let's look at a simplified model of a typical company:

We have deliberately refrained from mapping special cases - although Hypersoft offers comprehensive solutions for this, e.g:

-

Return deliveries to suppliers

-

Returns from points of sale to warehouse

-

Loss postings

-

Consumption due to manufacturing tolerances

Principle:

Each goods movement should be represented in the system by a corresponding goods posting. The Hypersoft Suite provides you with numerous functions from which you can choose the right combination for your business.

Why automation enables a rethink

You can theoretically automate 100% of your goods movements. This not only leads to a considerable reduction in workload, but also changes the sense of responsibility within the team - with consistently positive effects:

-

clear responsibilities

-

better transparency

-

fewer losses

-

reliable availability

-

significantly lower error rate

To illustrate this mindshift, we compare typical processes before and after the introduction of Hypersoft Stock Management:

Old procedure vs. new procedure with stock management

Conclusion

Reliable stock control is not only the basis for all automated goods movements, but also the key to greater profit, transparency and operational security.

Those who control can automate.

Those who automate increase sales, quality and efficiency.

Further topics:

How do I structure my inventory management?

How do I structure my item master?

How does the inventory service work?

Getting started with the controller

Back to the overarching topic: Stock Management