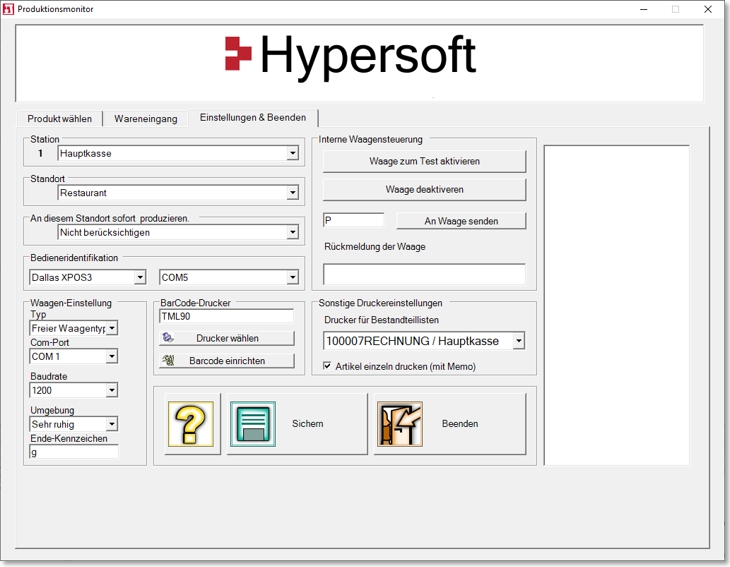

Setting the Production Monitor

You can adjust the behavior of the production monitor. You determine whether a login is required and whether a scale is connected. Optionally, a barcode printer/label printer can be connected and the print details can be selected.

Start the program Setproduction monitor from the program group Controller settings.

| Element / Switch | Function / Description |

|---|---|

| station |

Select the station. When the program executes postings, the station name is saved with the postings. For this purpose, a multifunctional station is to be set up in the ward administration. Even if you start the production monitor at a checkout station, it is better to set up your own station that is assigned to the production monitor. |

| Location | Choose Location to assign the production monitor to a trading area. This has a direct influence on the CONTROLLER, as the products trigger bookings when they are repacked at the respective sales outlet. The stock part lists of the recipes assigned to the products change the stock of the base items involved and create corresponding products. |

| Produce immediately at this location |

To ensure that the production monitor also supports Immediate production, select the entry Produce immediately if required from the list. |

| Operator identification | Select the lock that will be used to log in the operator and the port. If you want to use goods receipt control without logon, choose No identification from the list. |

| Scales Setting |

The scale interface has been discontinued. |

| Barcode Printer |

The TM-L90 from Epson can be used as a barcode printer. For this printer the standard Windows drivers must be installed and this driver is then assigned to the production monitor with the button Select printer. Use Set up barcode to design the label. Further topics: Set up barcodes |

|

and Print item individually (Memo) |

Select the printer to be used for component lists. Printing stock part lists is a special function of the Production Monitor. If the check box Print items individually (with memo) is activated, the parts lists are printed individually per item and the memo field from the item master is added below it. If the switch is off, all components of all produced items are summed up. Further topics: Remember |

| Save | Press Save to save your settings. |

| Exit | Exits the settings. |

Back to the overarching topic: Production monitor