Define stock specifications

The stock defaults contain your knowledge about the stock requirement of items. The MRP monitor can use these specifications to identify the need for items and automate their subsequent delivery.

Even extensive automation requirements can be made available to the Hypersoft system as unambiguous information, so that it monitors your inventory and creates internal delivery instructions on a daily basis exactly as you would do it yourself.

One of the advantages of entrusting this task to a computer system is that, in conjunction with the cash register systems, it can use "just in time" information on consumption to make the right decisions. In addition, the controller relieves you at this point with exact tasks, the traceable documentation and stock movements of which can be stored and evaluated at any time.

Items are assigned to a delivery point for suppliers (main warehouse) and stocked from there to points of sale. The settings determine which items are available where and name the source and destination. This also results in the internal transport routes (which can also be defined via further points of sale), which are then supplemented with the stock specifications for automation.

Requirements of the stock specifications

To be able to use the stock specifications to determine the item requirement, at least one row with valid values must be created for each item involved in the main warehouse. Here it is irrelevant for which storage location or which point of sale calculations are to be carried out. The entry of at least one stock specification per item is a must. You can also enter zero as the target and minimum stock value.

The 4 types of stock specifications

The stock specifications consist of four types:

- Multiple time Stock specification or Daily static stock specifications (alternative per sales office)

- Fill Inventory Default

- Reduce Inventory Specification

You select the selection with times or not to work in the stock defaults.

The time stock specifications for controlling the MRP monitor are defined by the selection of a time and the further optional differentiation of the weekdays /publicholidays. The daily static stock specifications apply to the whole day and can also optionally be entered differentiated for weekdays and holidays.

The smallest unit is a static stock specification for one day. You can use this one preset daily for replenishment and stocking and do not need to enter any other presets (if one stock preset is sufficient). This can be the right solution for a bottle rack, for example, in which exactly 58 bottles fit.

Further topics: Use times for placement

Multiple Time Inventory Specification as Example

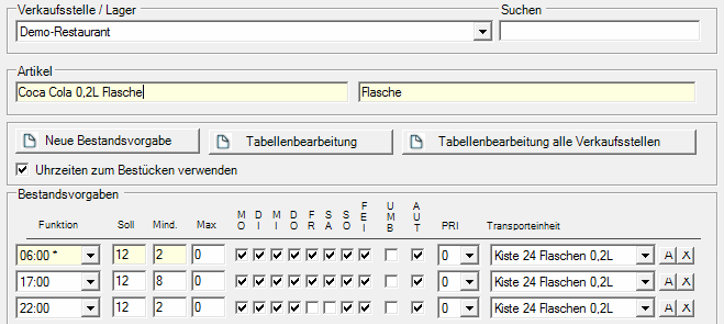

The figure shows the stock requirement of the item Cola 0,2 (this is a base item - a portion bottle) at the point of sale with the description demosystem.

Let's start with line 1: From the beginning of the day there should be 12 bottles. If the stock falls below 2 bottles, the MRP monitor creates a delivery instruction that fills the stock to 12. Since you do not wait at the beginning of the day until the minimum stock level has been reached, you have manually triggered a stocking of the point of sale to the target stock level of 12 beforehand, thus ensuring that all items are filled to the target stock level first.

Line 2: At 17:00 you want to make sure that the point of sale now has at least 8 False Cola 0,2. If this number is not reached, 12 bottles are filled. This applies on any day except public holidays, as you have unchecked the box in the FEI column.

Line 3: From 22:00 you only want to refill to 6 bottles if the minimum stock of 2 bottles is not reached. This applies on all days except Fridays and Saturdays, since you have removed the checkmarks in the FR and SA columns. On these two days, line 2 remains the default until the end of the day.

The delivery instruction in MRP mode calculates the stock specifications of the type time (optional date) and compares the target and minimum stocks with the current actual stock (or better: theoretical actual stock) to create delivery instructions.

Filling, loading and reducing

Instead of a multiple or static inventory specification, you can also select and set specifications of type Fill and Reduce. These two types are addressed manually using corresponding functions in the MRP monitor.

The Supplence type is intended for stock defaults that are not to be communicated immediately (Just In Time). If you were to use the Time type, it would be of no use, for example, on Sundays in the middle of high business hours if the MRP monitor wants to order from vendors. Ordering from suppliers is initiated by a person at a given time. Therefore, choose the Supplement type and enter the stock specifications there. If you then want to order from vendors, choose the Refill to targetstock function.

The Load function also refers to the Timetype. In contrast to the automatic Just In Time delivery during operation, you equip all stock specifications with the values of the target stocks so that you have optimally prepared the workstations. Afterwards (during operation), the stock is monitored by the MRP monitor.

The Reduce type is only intended for certain items or storage locations that are not to remain at the destination. For example, items must be returned to the cold store at the end of the day, or they are simply collected centrally and posted as unsaleable goods for loss. To reduce, first deactivate the point of sale's participation in materials planning (if valid stock specifications are still active, merchandise would otherwise be requested immediately after reduction) and choose Reduce.

The different types are set up for each item and storage location so that they can be accessed later, depending on the possible action.

The Repost function allows you to

This setting is very important when you are dealing with the stock specifications of a storage point that supplies other sales points or storage points.

Make sure that the storage locations from which you supply yourself internally have activated the transfer posting. In the tools there is the possibility to switch the switch for all items at the same time.

In the UMB column, each row of the stock specifications can have the option Transfer Posting Allowed. A warehouse or point of sale with rebooking allowed offers its item preferentially if it is needed at another point of the site. For example, from a certain time before the end of the day, you may want to transfer perishable goods rather than order new goods from stock or production. When reposting, the MRP monitor takes into account whether the source has sufficient items and only reposts stocks above the current minimum stock level. A delivery instruction is created on the MRP monitor, from which the point of sale for collection and the point of sale for delivery are specified.

Each line of the inventory defaults has the option AUT for Automatic. A stock specification participates in MRP with this setting. If you switch off AUT by removing the check mark, the disposition monitor will not automatically use this line.

In the tools there is the possibility to switch the switch for all items at the same time.

The individual stock specifications can have a different priority by setting this in the PRI column (default 0). You can therefore make individual stock specifications more important so that they are sorted upwards in the MRP monitor.

For example, only one barrel of beer can be stored at a point of sale. If a new item has to be delivered there, only one item is missing, but this is more important than the absence of other 10 items for which there is still a remaining stock (from minimum stock to zero). You could therefore set the priority for the barrel to 1 and thus one level higher than 0.

Further topics:

Mounting, Filling and Reducing

Back to the overarching topic: Controller settings