Kitchen Full Station

The importance of groupings

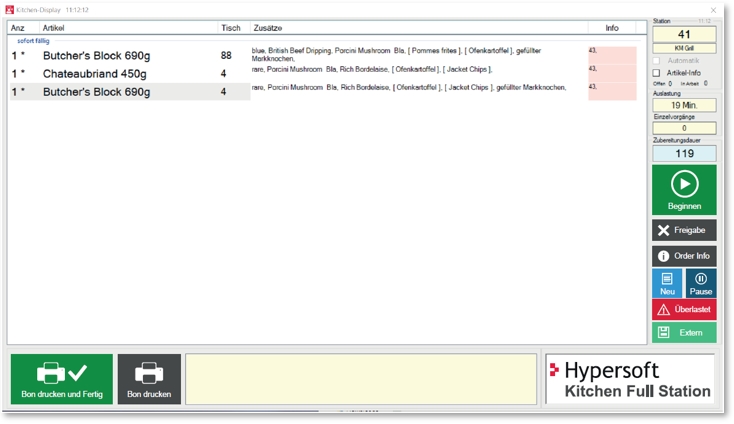

The Kitchen Full Stations group orders to communicate their due dates.

The In Work group shows items whose preparation has been confirmed. This also allows other displays - those involved in the order - to recognize that preparation has begun.

Next, the group shows a preview of items that have been ordered but are ready to be prepared. If the items are not processed for a certain period of time, they switch to the Immediately Duegroup.

The Immediately Due group shows items that are due but have not yet been started. With the change to Immediately Due a delay of the preparation begins; - a jam, which should be worked off.

The further grouping takes place on the basis of the minutes to the due date - i.e. the minutes to the beginning. It is possible to start these orders in advance, but this can lead to the item being completed too early.

The operator can optimize at his own discretion by selecting the same items from underlying groups and confirming with Start. However, he must consider the consequences if this item is finished too early!

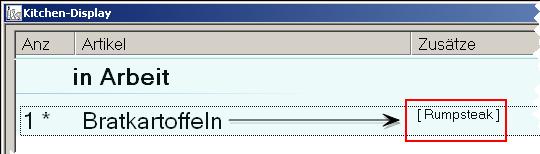

Multiple displays with one item

For example, if you order a steak plate with fried potatoes, the steak is to be shown on one display (workstation) and the fried potatoes are to be shown on another display (see capacity requirements), then the Kitchen Supervisor converts the item booked by queries or Free Attachments into individual items and displays them on both Kitchen Full Stations. The Kitchen Full Station with the steak receives the information that fried potatoes are being prepared for this and the Kitchen Full Station with the fried potatoes receives the information that these are to be served with a steak.

The preparation times of the forced query or the Free Annex are used on the basis of the component list of the item contained therein.

Example of the Kitchen Full Station, which has to start with the rump steak (employee is late):

Example of the Kitchen Full Station, which already prepares the fried potatoes and has started with them.

The square brackets mark the main item for which this order is a supplement.

However, you can also address another Kitchen Full Station without having to use queries or free attachments. For this you can (exclusively!) use the first query.

In this example the salad is sold with a fresh bruschetta. The bruschetta is marked as the only item in query 1 - this does not set the query, but the bruschetta is displayed as a single item (with the indication of belonging to the salad) on the Kitchen Full Station. The preparation time is used from the item Bruschetta. Other components can also be added without query, these are simply taken into account for merchandise management purposes. However, no further queries may be added to this variant.

Item distribution to the Kitchen Full Stations

If several workstations can produce the same items and all Kitchen Full Stations are used at the same capacity, the distribution is carried out on the basis of the station number, starting with the lowest number.

For further distribution, the utilization of the Kitchen Full Station is taken into account in such a way that the items are preferentially assigned to less utilized Kitchen Full Stations.

If the optimum in the capacity specifications is only set for a Kitchen Full Station, the Kitchen Full Stationwhere the optimum matches the order will be given priority.

With this function, however, only individual postings are distributed. Within a booking with a number higher than 1, you cannot split and then split.

Outside home functions at the Kitchen Full Station

Create a concept for the optimal use of the out-of-home function in your business and then use the specific possibilities.

A special out-of-home function is only supported on the Kitchen Full Station:

In the Kitchen Full Station settings, you can define a table number that automatically treats an operation as an off-site operation. Under Indicator, for example, you enter AH so that these bookings are marked with it at the Kitchen Full Station. A consecutive number is generated for each transaction with this table number, which is combined with the freely selectable indicator. Example: AH1 , AH2, AH3... Each time the Kitchen Supervisor is restarted, the system starts counting from 1 to 100.

In the standard system, the Outhouse status can be activated using the corresponding function in the POS system. So AH-13 booked for table 13 with AH function.

Set up function outside the house

Special marking for out-of-home operation

Customer transactions are displayed with the customer numbers, example K:3467. For postings with the FUNCTION "Outside house", the indicator is added Example: AH-K:4711

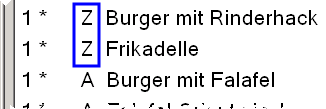

Items linked via information from queries or free attachments are given a letter to indicate their affiliation. The letters are assigned by the Kitchen Supervisor from A-Z and then begin again at A. The same letters are also displayed at the other stations (which are involved in the preparation of the order).

The letters can be switched off:

Info items at the Kitchen Full Station

Further information, such as the type of roasting (rare, medium or well done), can be selected as info items about queries, without these having to be managed in the capacity specifications. The selected info item is displayed in the Extras column of the main item.

Synchronization and Capacities

The Kitchen Supervisor takes into account the number and resulting additional time that an item can be produced simultaneously, we call this kitchen capacity. Example: 4 portions of noodles can be made in a wok, the first one lasts 240 seconds, for each additional one 40 seconds of cooking time are added.

The kitchen capacities can be defined differently according to the day of the week and additionally every 30 minutes. Examples: Cook between 12:30 and 14:30 only if at least 2 portions are needed at the same time. From 15:00 this workplace can no longer prepare items from the grill. The coordination and grouping of items at the Kitchen Full Station is always based on whole minutes, which are rounded off. For example, if an item is due in 5 minutes and 50 seconds, it is considered due after 5 minutes.

If the employee whose item has lasted the longest cannot start yet, the Kitchen Supervisor also stops the start of all other items involved accordingly. The group for the minutes to start will be recalculated and the orders assigned to them.

Automatic function or manual starting

Normally the Kitchen Full Station is controlled manually. The cook/preparer selects the items to be prepared and confirms this by pressing the Startbutton.

The KITCHEN MONITOR system automatically selects the next item due for preparation with the automatic function (setting) switch and moves it to the workin progress area.

The automatic function is practical, for example, if the operator does not intend to intervene in the sequence. The operator can process all orders in sequence. This setting is also very practical for a beverage dispenser.

Further topics:

Back to the overarching topic: Kitchen Monitor System