Variants and techniques of the Kitchen Monitor

The possibilities of the KITCHEN MONITOR system are as varied as the hospitality. It therefore consists of a selection of different monitors with special layouts, which can be adapted exactly to your needs using a variety of settings.

Some restaurateurs have in-depth experience or specific ideas about the required functionality of process control systems. Others, on the other hand, can rely on our consulting, as well as on specialized trade partners, who are trained on the KITCHEN MONITOR system, in order to analyze their needs and optimize their processes. On this basis, we work with you to develop your individual requirements and implement the KITCHEN MONITOR system in your work processes. Subsequently, we can accompany you in practice and successfully optimize the system together with you. This takes place in the practical use of the new system in your kitchen or preparation area.

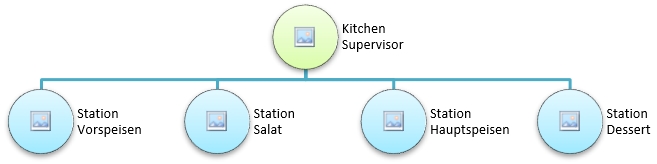

Control unit: Kitchen Supervisor

The Kitchen Supervisor is the central control unit between the POS system and the KITCHEN MONITOR system. It can be started directly at a Hypersoft POS system or run on an extra device.

The Kitchen Supervisor works fully automatically during the entire production process, but can provide a detailed overview of all monitors and items if required. This allows you to identify any weaknesses in the production process and, in extremely rare emergencies, even replace a defective monitor by sharing it with another monitor.

- Optimized for touch screen, mouse.

Further topics: Kitchen Supervisor

Monitor type: Kitchen Full Station

This monitor type supports the advertiser function. Compared to the Kitchen Row Station, it offers the widest range of functions. In addition, some functions overlap with functions of the other monitor types (Row Station, Workflow Manager).

Kitchen full stations with advertiser function work in parallel. Each item has its own Kitchen Full Station. This represents current due and future tasks.

In this example with direct completion without subsequent process stage with own workflow manager:

- The graphic elements and the layout are largely fixed. These can only be adjusted to a limited extent.

- Optimized for touchscreen control, but also supports a bump bar.

Further topics:

Special feature: advertiser functions

Monitor type: Kitchen Row Station

The Kitchen Row Station displays only "due" items in tabular form according to the item. Here each item receives a certain sequence in the table, which is calculated on the basis the time of the reservation and/or the release of a reservation at the cash and the preparation times specified in the item master for the booked items (plus any query items). The special features of each item and useful information from the order are presented in concentrated form. Multiple tools help to optimize production times.

- The graphic elements and the layout are extensively configurable. Colors / sizes / fonts / number of rows & columns can be configured in detail.

- The operation is best done with the Bump Bar (touch screen is also supported). With the Bump Bar the monitors can also be placed higher/external range.

Further topics:

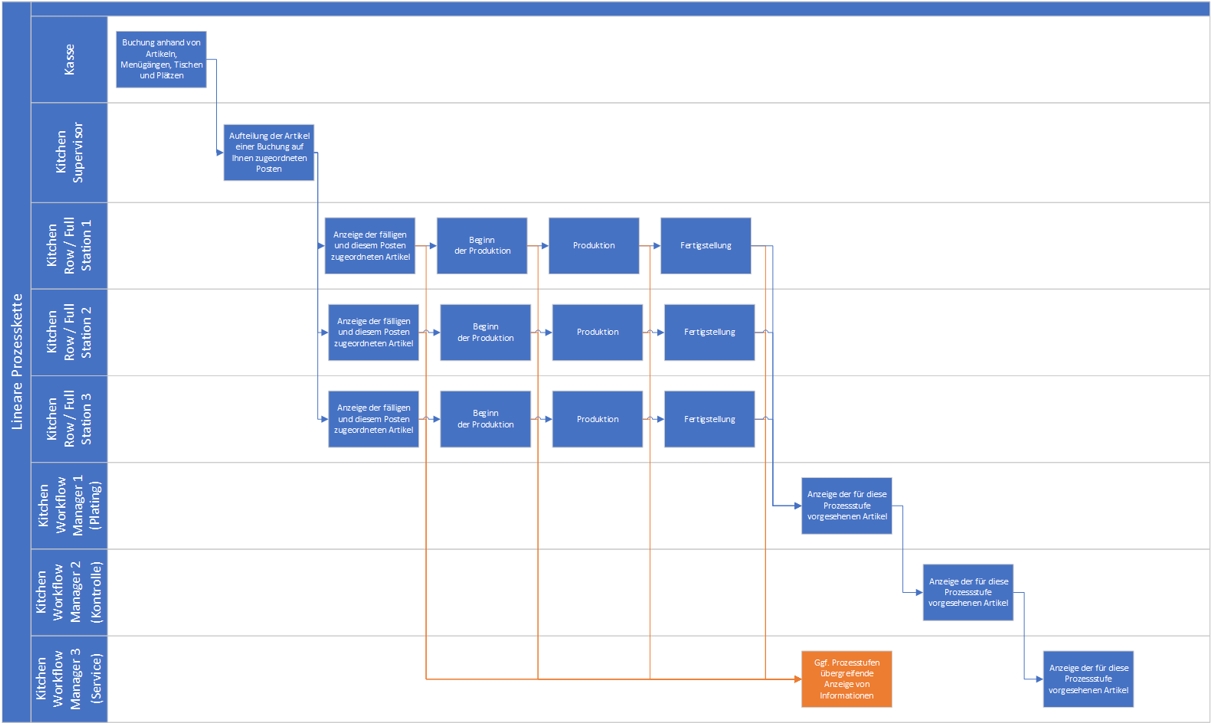

Monitor type: Kitchen Workflow Manager

The Kitchen Workflow Manager is used within the process chain that an order goes through, subsequently to the Kitchen Row /Full Stations. After the items have produced the items assigned to them and marked them as completed, they are transferred from the Kitchen Row /Full Stations to the next stage of the process chain and thus to a Kitchen Workflow Manager. A maximum of 4 process stages are possible subsequently to the items to be produced. Thus, a linear manufacturing process with defined transfer points can be represented. The depth of the information provided to individual Kitchen Workflow Managers is adjustable. For example, it is possible for individual Kitchen Workflow Managers to provide information on items that are assigned to the process stage assigned to them at a given time and, in addition, information on items that are assigned to the previous process stages. This serves to obtain a complete overview of the status of individual orders at defined stages of the process chain. Furthermore, it is possible for a Kitchen Workflow Manager to intervene in the process of the respective upstream stage and change the status of an item or order in order to assign it to the next process stage. This enables your employees to support each other in case of capacity bottlenecks.

A possible process chain would therefore be:

- The graphic elements and the layout are extensively configurable. Colors / sizes / fonts / number of rows & columns can be configured in detail.

- Optimized for bump barcontrol, but also supports a touch screen.

Further topics:

Settings of the Kitchen Workflow Manager (and Preview Manager)

Monitor type: Kitchen Workflow Manager as Preview Manager

In the design of a workflow manager, all bookings are displayed in advance.

Further topics: Kitchen Preview Manager

Monitor Type: Kitchen Table View

- Pure display of the operations, no operation of the elements provided.

Further topics: Kitchen Table View

Monitor type: Goods issue

The goods issue is an issue monitor directly to guests. It can be applied as an option to all monitors.

- Optimized for touch screen.

Further topics: Kitchen goods issue

Special function: Whole kitchen / Half kitchen

With this function you can support two alternating situations of your kitchen setup. Example: Under full load you work with two kitchens, under partial load only with one.

If you would like to work like this read more here...

Special feature: advertiser functions

Some variants of the KITCHEN MONITOR System II support advertising. But what about advertising with the KITCHEN MONITOR?

In normal or medium-sized kitchens (up to approx. 1,000 preparations / plates per shift), the timing for joint completion may also work without an advertiser. The same applies to a simplified offer and, of course, to companies where timely completion is not part of the concept. For everyone else there is the advertiser or the advertiser.

The advertiser / the advertiser coordinates the orders at the output between the kitchen and the service. Usually he reads the order vouchers and calls the orders together with special requests into the kitchen. This demanding activity optimizes the collaboration between kitchen and service.

The advertiser has knowledge of and takes into account the different preparation times of orders that are to be served at the same time later. He also knows the limits of individual items (capacities) and sensitively adapts the preparations to the circumstances.

The KITCHEN MONITOR system can also advertise. It takes into account different preparation times of orders to be completed at the same time and gives timely instructions to each item. The KITCHEN MONITOR system can also sensitively adapt the preparations to the maximum advantage for you and your team by means of the capacity management (of devices and workstations).

The first step is to adjust cooking times, for example for steaks. Such things are easy to control. However, if you decide to advertise the entire kitchen (or a large part of it) it means that the information about preparation times and capacities.

If you work with full advertisement you have to use the Kitchen Full Station monitors and store extensive master data regarding preparation times and capacities. This is the highest level of kitchen automation with monitors.

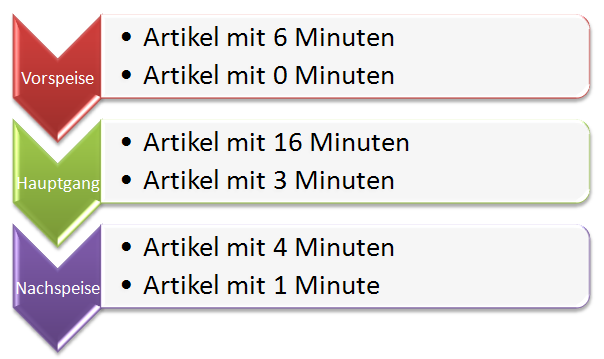

Special feature: Preparation times with menu courses

The synchronization of orders with the aim of simultaneous completion always refers to the currently booked items of a transaction. With one menu option, you can group these bookings together to ensure completion per menu option with several menu options within a single operation. For example: first all starters, then all main courses and then all desserts.

To do this, you must work with the cash register function Menu access Release. The menu item Release can be carried out manually or automatically.

The manual menu item Enabling

An operator must transmit the following aisle to the Kitchen Supervisor or Delayed Order Control by enabling it at the POS or MPOS.

Without the release of a menu entry, the items are not managed by the Kitchen Supervisor - they would never be delivered.

Automatic release of the first menu entry

As a rule, the production of the first menu should also be started when the order is entered. A corresponding setting is provided so that the 1st menu section automatically receives a release.

Automatic release from 2. menu

After completion of the last item of a menu a timer is started, which automatically releases the next booked menu after a predetermined time. The completion for the start of the timer is indicated by the corresponding confirmation (Ready) on the KITCHEN MONITOR system. To set the times, store the corresponding number of minutes for the timer in the program menu courses.

Further topics: Menu courses and pressure schemes

Excluding items from the Release menu option

If you work with menu item release, you can order items whose delay is not wanted (for example beverages) before the release of the menu item (i.e. immediately). There is a switchin the ward management for this purpose. Items to which no production time has been allocated therefore do not participate in the delayed order receipt control.

If you also want to use this setting to include items whose production time is 0 (zero), enter this production time and assign these to such items.

Example of use...

An example: You have created the beverages without production time. Your operators book the drinks together with the food - into the menu courses - but want the drinks not to be ordered with a delay. This activates this function. If you would like individual items to be ordered with the menu courses without actual production time, assign at least production time 0 to them.

Further topics:

Do not withhold items without production time

Special feature: roasting method prolongs preparation time

The roasting method determines the preparation time for the steak (rare, medium, well done, to name just a few). The KITCHEN MONITOR system can calculate the preparation time based on the roasting method. To do this, store the desired roasting methods and the additional preparation time for these. The system then adds the respective preparation time of the type of roast to that of the steak and uses this for timing/advertising. Example: two people order the same steak, one medium, the other rare. The difference is 3 minutes based on your settings. The system requests the start of grilling the medium steak 3 minutes before grilling the rare steak. Both are perfectly grilled at the same time.

Characteristic: - Extra long preparation time

You have items whose preparation time cannot be compensated in the normal production process. In our example, a tomahawk steak takes 40 minutes. The service sells as 1. The waiting time can be shortened by eating appetizers in the aisles. The Tomahawk steak is set to immediately display in 1st gear to production. Later, when the other items are due for production, they will appear suitably advertised (also by type of roast) on the Tomahawk steak. Of course the gear release for the main courses must be considered here.

Special feature: Beverages

During a test operation at a beverage dispenser and bar, we found that a clearly visible monitor (with simple sequence and setting) can make a significant contribution to increasing speed and work ergonomics. The difference alone, that the orders are immediately visible (and not only a receipt must be grasped, read, noted and filed) optimizes this area. In addition, summaries can further accelerate the production of cocktails and the like (by foresight).

When finished, a talon is quickly printed and attached (still unused and clean).

We recommend equipping every loaded beverage counter and production area with a Kitchen Monitor.

Special feature: Station image

Display the Kitchen Monitor on another station. To set up, see Kitchen Monitor Station Image.

(Emergency solution: Delayed order receipt)

The following description is an alternative to the KITCHEN MONITOR system for small requirements: If you only want to create a simple delayed order voucher, you can use the settings of the KITCHEN MONITOR system to synchronise the preparation (like advertising). If required, you will then receive delayed order receipts by means of automatic synchronization of the completion according to the preparation times (included in every Hypersoft POS license). An additional licence for the Hyperosft POS is not required.

Our experience shows, however, that this procedure is unfortunately not sufficient in practice to control complex processes, many items and optimum processes without problems, as it quickly overtaxes the cooks/preparers. Kitchen Supervisor

Further topics:

Time-delayed order receipt control

Back to the overarching topic: Kitchen Monitor System